The battery is not just one component among many in an electric vehicle — it is the core system around which the entire car is engineered. Range, acceleration, charging speed, safety, cost, resale value, and even interior layout depend directly on battery design. Unlike a fuel tank, which is passive storage, an EV battery is an active electrochemical and digital system that constantly measures, adapts, and protects itself. To understand modern electric cars properly, it is necessary to look at the battery not as a single object, but as a multilayer energy platform.

The Battery Pack as an Integrated Energy System

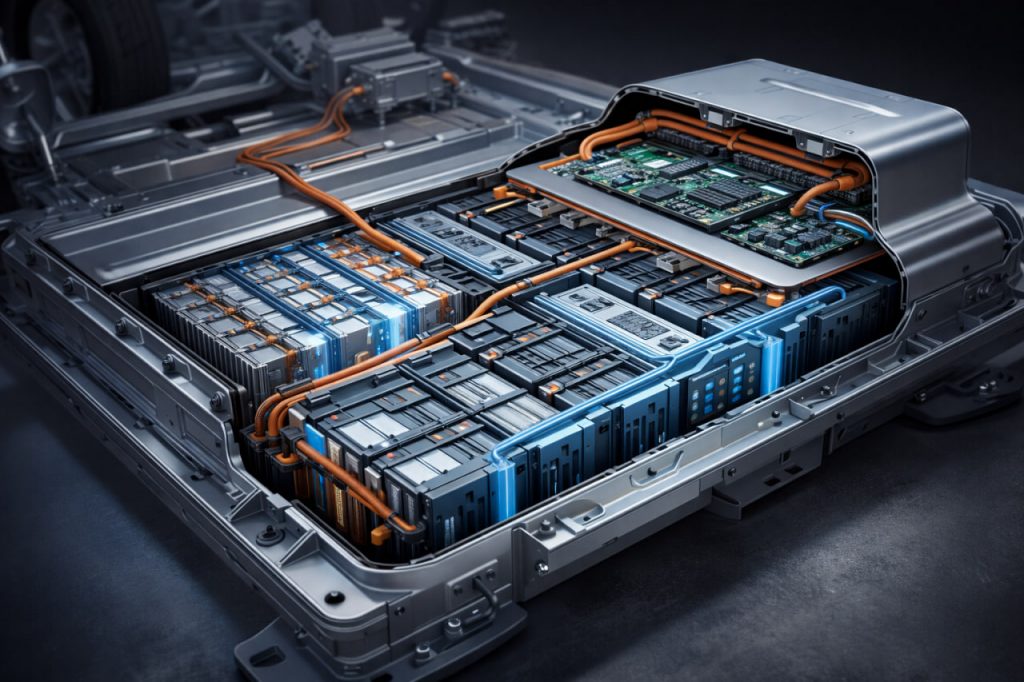

What is commonly called an “EV battery” is in reality a battery pack, a complex assembly that integrates electrical, mechanical, thermal, and software subsystems. The pack includes thousands of cells, organized into modules (in most designs), enclosed in a rigid housing that often forms part of the vehicle’s structure. High-voltage electronics, cooling circuits, sensors, and safety mechanisms are all embedded inside this unit. Modern EV platforms are designed around the battery from the very beginning, allowing manufacturers to optimize weight distribution, rigidity, and crash performance.

“In modern EVs, the battery pack is no longer just stored inside the car — it effectively is the car’s foundation,” — Dr. Marcus Feldman, battery systems engineer.

Battery Cells: Chemistry and Energy Storage

At the most fundamental level, energy is stored in battery cells, each acting as a small independent energy unit. The majority of electric vehicles today rely on lithium-ion cells, which offer a strong balance between energy density, efficiency, and durability. Each cell contains a cathode, anode, electrolyte, and separator, enabling controlled movement of lithium ions during charging and discharging.

Different chemistries are chosen for different goals. NMC (nickel–manganese–cobalt) cells prioritize high energy density and long range, while LFP (lithium iron phosphate) cells offer lower cost, longer cycle life, and improved thermal stability. These choices influence not only range but also charging behavior, degradation rates, and cold-weather performance.

Modules and Pack Architecture

In most designs, cells are grouped into modules, which serve as intermediate building blocks between cells and the full pack. Modules simplify manufacturing, testing, and thermal control while allowing defective units to be isolated. Electrical connections inside modules are carefully engineered to balance voltage and current while minimizing resistance and heat.

Some manufacturers are moving toward cell-to-pack or even cell-to-structure designs, eliminating modules to increase energy density and reduce weight. This approach improves efficiency but places greater demands on cooling, monitoring, and safety engineering. The architectural choice reflects a trade-off between flexibility, serviceability, and maximum performance.

The Battery Management System (BMS): Digital Control Layer

The Battery Management System (BMS) acts as the battery’s digital brain. It continuously monitors individual cell voltages, temperatures, current flow, and overall state of charge (SoC). The BMS also calculates state of health (SoH), estimating long-term degradation and remaining usable capacity.

Crucially, the BMS enforces operating limits that protect the battery from damage, such as restricting fast charging when temperatures are too low or reducing power output when overheating is detected. Cell balancing ensures that no single cell becomes overstressed, which would otherwise accelerate degradation.

“Battery longevity is determined less by chemistry alone and more by how intelligently the system is managed,” — Dr. Elena Rossi, electric powertrain specialist.

Thermal Management: The Hidden Key to Battery Longevity

Temperature is one of the most critical factors influencing battery performance and lifespan. Modern EVs use sophisticated thermal management systems, most commonly based on liquid cooling, to keep cells within a narrow optimal temperature range. Coolant channels run alongside or between cells, extracting heat during high-load driving or fast charging.

In cold conditions, the system can actively warm the battery, improving efficiency and preventing lithium plating during charging. This thermal control allows EV batteries to deliver consistent performance across seasons and is a major reason why automotive-grade batteries outperform consumer electronics batteries in durability.

Structural Housing and Multi-Layer Safety Design

The battery pack is enclosed in a rigid structural housing, usually made of aluminum alloys or reinforced steel. This housing protects the battery from impacts, water ingress, and road debris while also contributing to the vehicle’s torsional rigidity. Internally, the pack contains fire-resistant barriers, pressure vents, and isolation mechanisms designed to manage rare events such as thermal runaway.

Safety engineering follows a layered philosophy: protection at the cell level, module level, pack level, and vehicle structure level. Even in severe crashes, modern EVs are designed to electrically isolate the battery to prevent hazards.

“Battery safety is not a single feature — it is an ecosystem of redundant protections working together,” — Dr. Thomas Nguyen, automotive safety researcher.

High-Voltage Systems and Power Delivery

Most modern EV batteries operate at 400 V or 800 V architectures, enabling efficient power transfer and faster DC charging. Higher voltage allows lower current for the same power, reducing heat losses and improving charging efficiency. High-voltage cables, contactors, and inverters are heavily insulated and continuously monitored to ensure electrical safety.

This architecture is what enables rapid acceleration, regenerative braking, and ultra-fast charging without excessive thermal stress.

Degradation, Aging, and Real-World Lifespan

Battery degradation is a gradual process influenced by charge cycles, temperature exposure, and time at high state of charge. Modern EV software limits extreme operating conditions, which significantly slows degradation compared to early-generation batteries. Real-world fleet data shows that many EV batteries retain a high percentage of original capacity even after hundreds of thousands of kilometers.

Smart charging strategies, such as finishing charging close to departure and avoiding frequent 100% charging, further extend battery life.

Conclusion

A modern electric car battery is a sophisticated fusion of chemistry, electronics, software, and structural engineering. From microscopic ion movement inside cells to large-scale thermal and digital control systems, every layer is optimized for safety, efficiency, and longevity. Understanding this architecture explains why EV batteries are reliable, why they age predictably, and why they are central to the future of transportation.