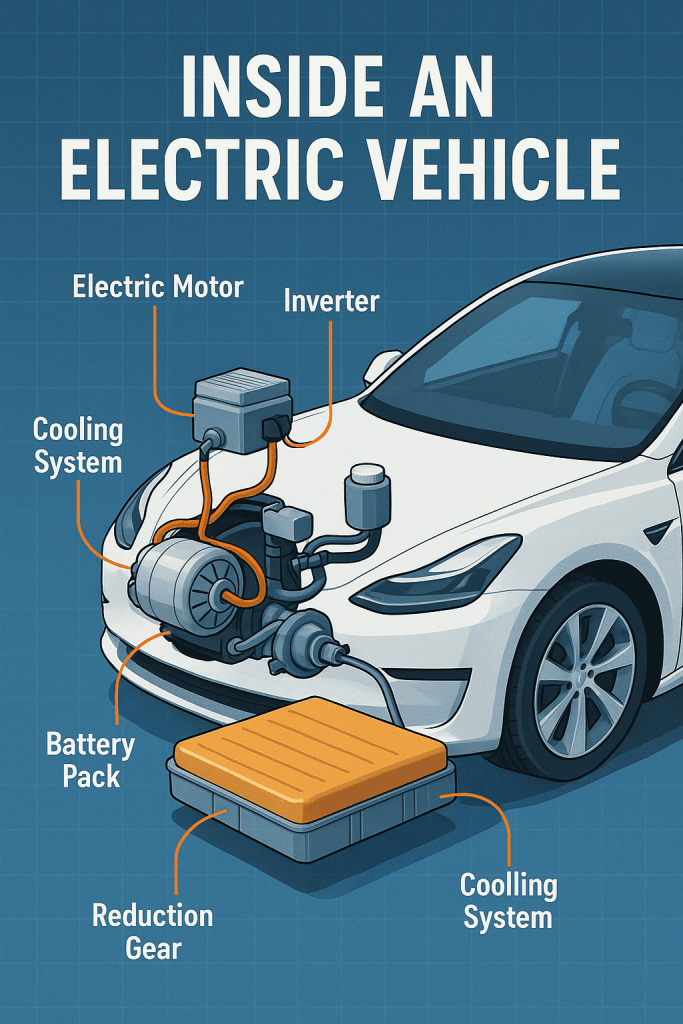

Electric vehicles (EVs) are transforming the automotive landscape with their innovative and efficient engineering. But what exactly lies beneath the sleek exterior of an EV? Unlike traditional internal combustion engine (ICE) vehicles, EVs have a simpler, more modular architecture—but it’s packed with high-tech components that work together to deliver instant torque, zero emissions, and a smooth driving experience. In this article, we’ll explore the essential technical components inside an electric vehicle, including the electric motor, reduction gear, inverter, battery pack, and thermal management systems.

Electric Motor: The Heart of Motion

At the core of every electric vehicle is the electric motor, which replaces the combustion engine. Most EVs use either an AC induction motor or a permanent magnet synchronous motor (PMSM). These motors convert electrical energy into mechanical energy to drive the wheels.

Electric motors offer several advantages over internal combustion engines: they are more compact, require less maintenance, and deliver instant torque, enabling rapid acceleration. Some EVs feature a single motor, while others use dual or even quad-motor setups for enhanced performance and all-wheel-drive capabilities.

Reduction Gear: Simplifying Power Transmission

Unlike conventional vehicles that require complex multi-speed transmissions, EVs use a single-speed reduction gear. This component reduces the high rotational speed of the electric motor to a level suitable for the wheels, optimizing efficiency and torque delivery.

Because electric motors can operate efficiently over a wide RPM range, there’s no need for gear shifting, making the drive smoother and more responsive. The result is fewer moving parts and increased mechanical reliability.

Inverter: Converting Energy for the Motor

The inverter is a critical electronic component that converts direct current (DC) from the battery into alternating current (AC) for the motor. In the case of DC motors, it controls the voltage and current to regulate speed and torque.

Modern inverters also enable regenerative braking, converting kinetic energy during deceleration into electricity that is sent back to the battery, increasing energy efficiency. The inverter also acts as a controller, dynamically adjusting motor performance based on driver input and real-time driving conditions.

Battery Pack: The Energy Source

The battery pack stores the electrical energy required to power the vehicle. Most EVs today use lithium-ion battery technology, composed of thousands of individual cells grouped into modules and then assembled into a pack.

Battery capacity, measured in kilowatt-hours (kWh), determines the vehicle’s range. High-capacity batteries provide longer range but increase cost and weight. Advanced battery management systems (BMS) monitor each cell’s health, voltage, and temperature, ensuring safe and efficient operation.

Thermal Management System: Keeping Temperatures in Check

To maintain optimal performance and prolong the lifespan of both the motor and battery, EVs use sophisticated thermal management systems. These systems include liquid cooling loops, pumps, radiators, and sometimes heat pumps.

The cooling system regulates battery temperature to avoid overheating during charging or fast driving, and it also maintains the inverter and motor within their operational ranges. Some EVs, like Tesla models, use integrated thermal systems that manage cabin climate and drivetrain components using shared circuits.

Onboard Charger: Managing Grid Input

The onboard charger is responsible for converting AC electricity from a home or public charger into DC electricity that the battery can store. The charger also regulates voltage and current flow to protect the battery and ensure safe charging.

Its power rating (typically between 6 and 22 kW) determines how quickly an EV can charge using Level 1 or Level 2 charging infrastructure. For DC fast charging, this function is bypassed in favor of external high-power systems.

Charging Port and Controller

The charging port is the physical interface for connecting the vehicle to a power source. It supports multiple connector types based on region and standard (CCS, CHAdeMO, Tesla, Type 2, etc.). A smart charging controller ensures safe communication between the EV and the charger, handling authentication, current flow, and safety checks.

Regenerative Braking System

EVs utilize regenerative braking to recover kinetic energy that would otherwise be lost as heat during braking. This energy is sent back into the battery, enhancing overall efficiency and extending driving range. The system also reduces brake wear, contributing to lower maintenance costs.

Electronic Control Units (ECUs)

Modern EVs rely on numerous ECUs and processors to manage everything from battery health and motor performance to infotainment and driver-assistance systems. These embedded systems are interconnected through a high-speed communication network, often using protocols like CAN (Controller Area Network).

Conclusion

Electric vehicles may appear simple from the outside, but they are powered by a complex and highly integrated set of components working in harmony. From the electric motor and inverter to the battery pack and cooling system, every part plays a vital role in delivering a clean, efficient, and responsive driving experience.

As technology continues to evolve, future EVs will benefit from lighter materials, faster processors, and even more compact components, making them not only more efficient but also more affordable and sustainable. Understanding what’s inside an EV helps drivers, enthusiasts, and investors appreciate the engineering marvels that are reshaping the future of mobility.

sounds complicated & expensive I dont mind that idea did work

This whole world looks like a mess, but it works😂

wow EV internals r insane 😎😎😎

ya sientist are insane!😁

man, so many peeps behind makin one car! 🤯

Haha, you dunno how many people be behind makin them processors 💀

too many parts, probs breaks 🙄