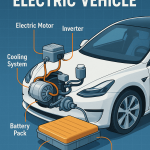

Electric vehicles (EVs) are becoming an integral part of modern transportation, driven primarily by advancements in battery technology. At the heart of these vehicles lie lithium-ion batteries, the current gold standard due to their efficiency, reliability, and high energy density. Understanding how these batteries function—from their chemical foundations to charging mechanisms—is essential to appreciate the rapid growth of the EV industry and to anticipate future innovations. In this comprehensive overview, we explore lithium-ion battery principles, different battery chemistries, charging methods, and promising next-generation technologies.

The Chemistry Behind Lithium-Ion Batteries

Lithium-ion batteries work through electrochemical reactions that enable energy storage and release. Each battery consists of four main components:

Anode (Negative Electrode): Typically composed of graphite, the anode stores lithium ions during charging. Graphite is used due to its high stability and excellent conductive properties.

Cathode (Positive Electrode): Made of lithium-metal oxides, the cathode releases lithium ions during discharge. Common cathode materials include lithium cobalt oxide (LCO), lithium iron phosphate (LFP), lithium nickel manganese cobalt oxide (NMC), and lithium nickel cobalt aluminum oxide (NCA).

Electrolyte: A conductive liquid or gel containing lithium salts facilitates the movement of lithium ions between electrodes. The electrolyte must remain stable across various temperatures and voltages.

Separator: A permeable membrane that physically separates the anode and cathode to prevent short-circuits while allowing lithium ions to flow freely.

During charging, lithium ions move from the cathode to the anode via the electrolyte and embed themselves within the graphite structure. During discharge, the ions reverse direction, traveling back toward the cathode, generating an electrical current to power the vehicle’s motor.

Types of Lithium-Ion Batteries Used in EVs

Several lithium-ion battery chemistries are tailored for specific performance metrics:

NMC (Nickel-Manganese-Cobalt): Known for its balanced performance, combining high energy density, thermal stability, and longer cycle life. Widely used in EVs such as the Chevrolet Bolt, Volkswagen ID. series, and BMW i3.

NCA (Nickel-Cobalt-Aluminum): Offers extremely high energy density, favored for long-range EVs. Tesla heavily utilizes NCA chemistry in its Model S, Model X, and Model 3.

LFP (Lithium Iron Phosphate): Prized for its safety, longevity, and lower cost. Though less energy-dense than NMC or NCA, LFP is increasingly popular in affordable models like Tesla’s Model 3 Standard Range Plus in China and BYD’s electric vehicles.

LCO (Lithium Cobalt Oxide): While widely used in consumer electronics, it is generally avoided in EV applications due to cost, safety concerns, and sustainability issues.

Battery Management Systems (BMS): The Brain Behind the Battery

A sophisticated battery management system is integral to EV batteries, constantly monitoring key parameters like voltage, current, temperature, and the state of charge. BMS functions include:

– State of Charge (SoC) Monitoring: Accurately tracks remaining battery capacity.

– State of Health (SoH) Management: Assesses battery degradation to predict lifespan and maintenance needs.

– Cell Balancing: Ensures equal distribution of charge across individual cells to prolong battery life.

– Thermal Management: Actively manages battery temperature, preventing overheating and improving efficiency, often using liquid cooling systems.

Charging Methods and Their Implications

EV batteries are charged primarily through two methods:

AC Charging (Level 1 and Level 2): Uses standard home or public AC power outlets. The vehicle’s onboard charger converts AC power to DC to charge the battery. While convenient, AC charging is relatively slow, typically suitable for overnight or long-duration charging.

DC Fast Charging: Supplies direct current (DC) straight to the battery, bypassing the onboard charger. DC charging stations drastically reduce charging times, allowing drivers to recharge to 80% capacity in approximately 20-40 minutes. However, frequent use can accelerate battery degradation due to increased thermal stress.

Battery Degradation: Understanding Longevity and Performance

All lithium-ion batteries degrade gradually due to repeated charge-discharge cycles and environmental factors. Key contributors to battery degradation include:

– Frequent fast charging, leading to elevated battery temperatures

– Operating in extremely hot or cold environments

– Regularly allowing battery capacity to fall below 10% (deep discharge)

– Keeping batteries consistently charged above 90% (high charge state)

Manufacturers typically guarantee battery performance, aiming for at least 70-80% of original capacity after eight years or approximately 160,000 km (100,000 miles).

Emerging Battery Technologies and Future Alternatives

Advancements in battery technology promise enhanced safety, higher energy densities, faster charging, and lower costs:

Solid-State Batteries: Replace liquid electrolytes with solid alternatives, significantly reducing fire risk, improving energy density, and enabling faster charging. Companies like Toyota, QuantumScape, and Samsung SDI are pioneering this promising technology.

Sodium-Ion Batteries: A cost-effective alternative to lithium-ion, using abundant sodium as the primary charge carrier. Currently less energy-dense, sodium-ion batteries could significantly reduce dependence on lithium and cobalt, especially in affordable EVs and stationary storage.

Silicon Anode Technology: Incorporating silicon into anodes greatly increases energy storage capabilities. Silicon anode solutions, developed by companies like Sila Nanotechnologies and Amprius, could soon become mainstream.

Lithium-Sulfur Batteries: Offer exceptionally high theoretical energy densities, potentially doubling or tripling current lithium-ion performance. Challenges in durability and stability remain, but continued research shows considerable potential.

Conclusion

Lithium-ion battery technology has rapidly evolved to become the backbone of the electric vehicle industry, delivering powerful performance, reliability, and efficiency. Understanding the intricate chemistry, diverse battery types, and the role of sophisticated management systems underscores the complexity behind modern EVs. As research accelerates, future battery technologies promise safer, more affordable, and even more efficient solutions.

From advanced lithium-ion chemistries to revolutionary solid-state, sodium-ion, and silicon-based batteries, ongoing innovations will reshape transportation. These advancements will not only extend driving ranges and accelerate charging times but also reduce environmental impacts, paving the way toward a truly sustainable automotive future.

Its exciting to see how solid-state and sodium-ion batteries could change!

I doubt they’re gonna change much at all lol 😂

Haha, dude up top, man you be so wrong it ain’t even funny 🤣 Just look at the stuff dey was doin’ in the 50s-60s and then look at the stuff now.

We have a good opportunity to replace the battery rather than charging it like cabs in China do 😎

lmao that battery pack is like 900+ pounds have fun swappin that out 💀

when will they invent a battery that never needs charging 🤔

never Not unless they literally rewrite physics, lol 💀

lithium batteries key for evs 🚗. complex stuff .safer & cheaper batteries is win!

Yeah, dat lithium really do mess up nature, I be hopin dey replace it. 😫

The future is electric and there’s no turning back. Every line in this article screams progress. Invest in batteries now or stay broke

I think, batteries is still not main problem of evs ..

But still, aint no other way to carry that juice, is there? 😅

lol batteries die quick af 👎

aint no fix, we all too dumb😂

ev batt tech r wild 👍👍is so cool!